WINISO®

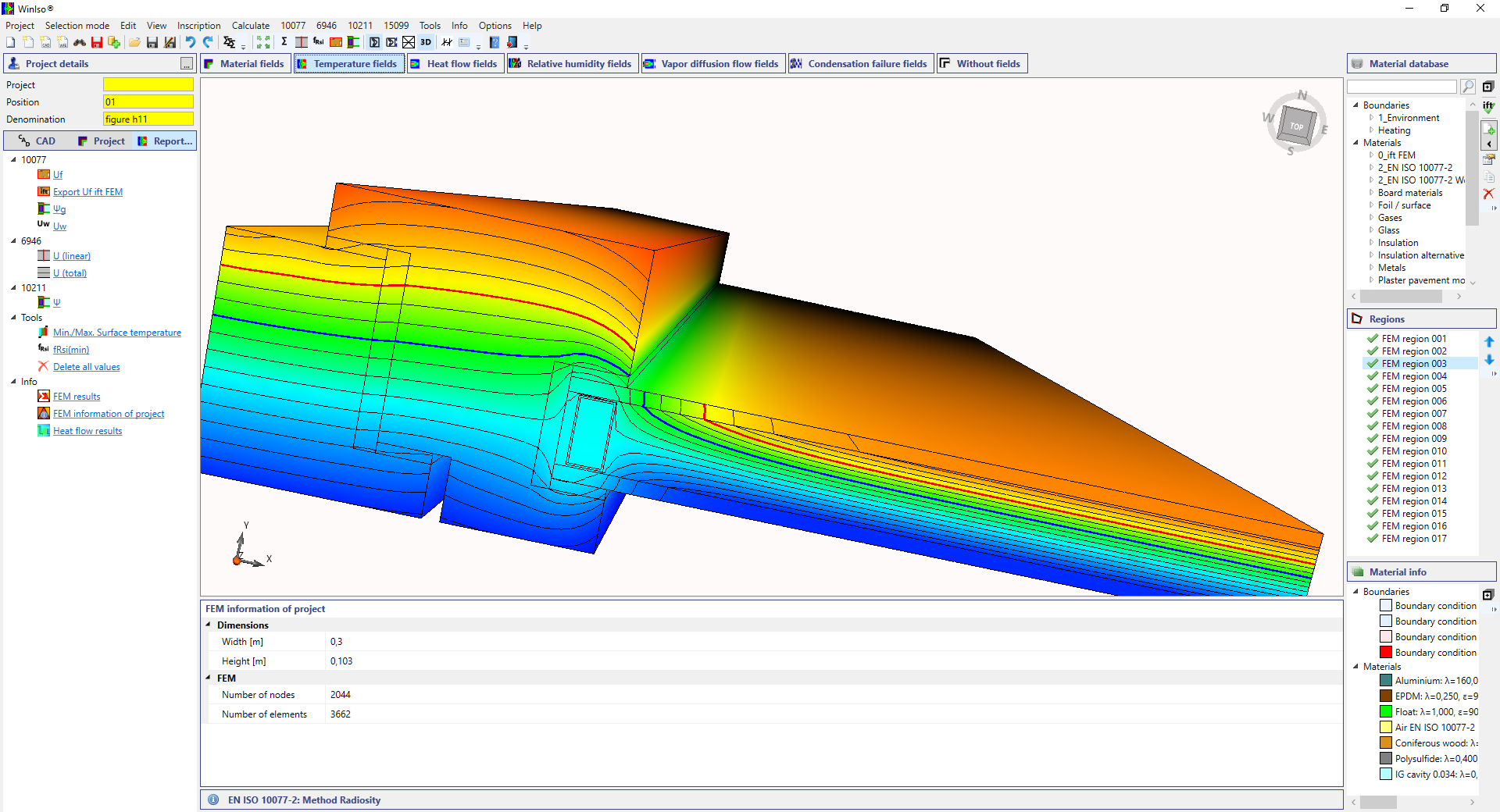

Calculation of heat flows, thermal bridges, isotherms and Uf values according to EN ISO 10077-2:2018 as well as Ufr, Ueg and Ucg values according to ISO 15099 and NFRC.

Professional calculation

Uf, Ψ, thermal bridges, isotherms, fRsi as well as Ufr, Ueg and Ucg values

Validated

according to EN ISO 10077-2:2017-07 and EN ISO 10211-2:2017-07

Powerful functionalty

for the thermal calculation of windows and facades

Imported CAD files can be prepared by automatic detection and correction of CAD errors. Thus, complicated components and systems can be analysed and calculated with short computing times and small data sizes. The integrated FEM calculation kernel enables the most accurate results.

Features

- Highly automated geometry preparation of CAD data (.dxf & .dwg)

- Detailed transfer of CAD data incl. radii and bevels

- New solver and new calculation core with automatic FEM meshing

- Automatic FEM meshing can be controlled flexibly and specifically, resulting in high calculation speeds

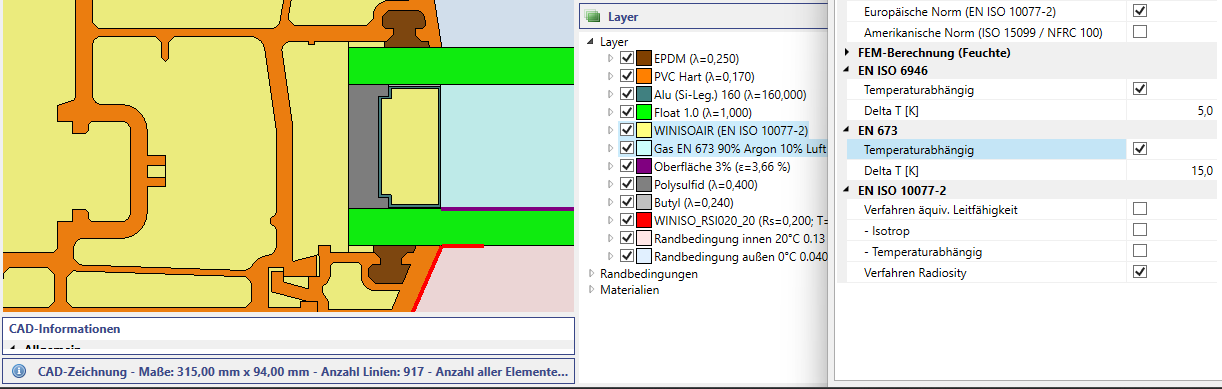

- Calculation according to the "radiosity model" (new cavity model according to EN ISO 10077-2:2018) and with equivalent conductivity (EN ISO 10077-2:2012/2018)

- Simple definition of foils, coatings and surface properties using line drawings

- Automatic material allocation based on CAD layers

- Gas filling for inter-pane spaces according to DIN EN 673 freely mixable

- Automated Uf calculation of window and façade profiles

- Psi-values of thermal bridges and insulating glass spacers according to EN ISO 10211 and EN ISO 10077-2

- Ug-values of multi-pane insulating glass according to EN 673

- U-values of any construction according to EN ISO 6946

- Calculation of isotherms, surface temperatures and temperature factor according to DIN 4108-2/-3

Test our demo version!

Why WINISO®?

- Certified by independent testing institutes

- Results are internationally recognised

- Extremely user-friendly operation

- Reliable partner for long-term customer satisfaction

- Market-ready solutions even before the relevant laws and standards are passed, together with permanent updating – our solutions are always up to date

Examples

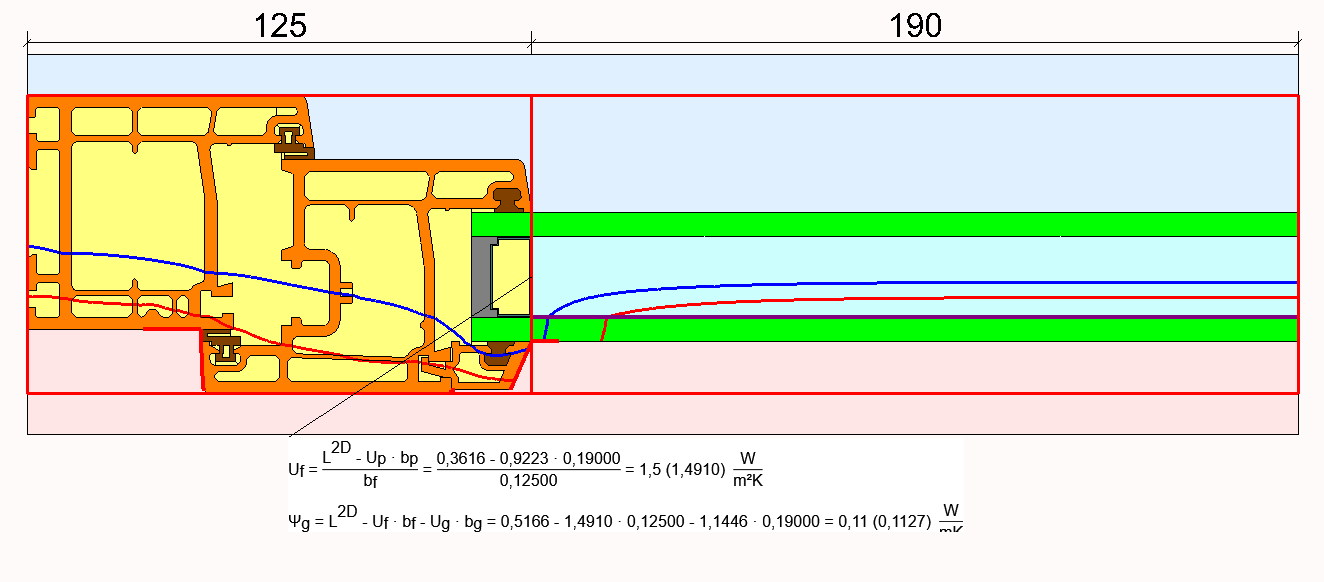

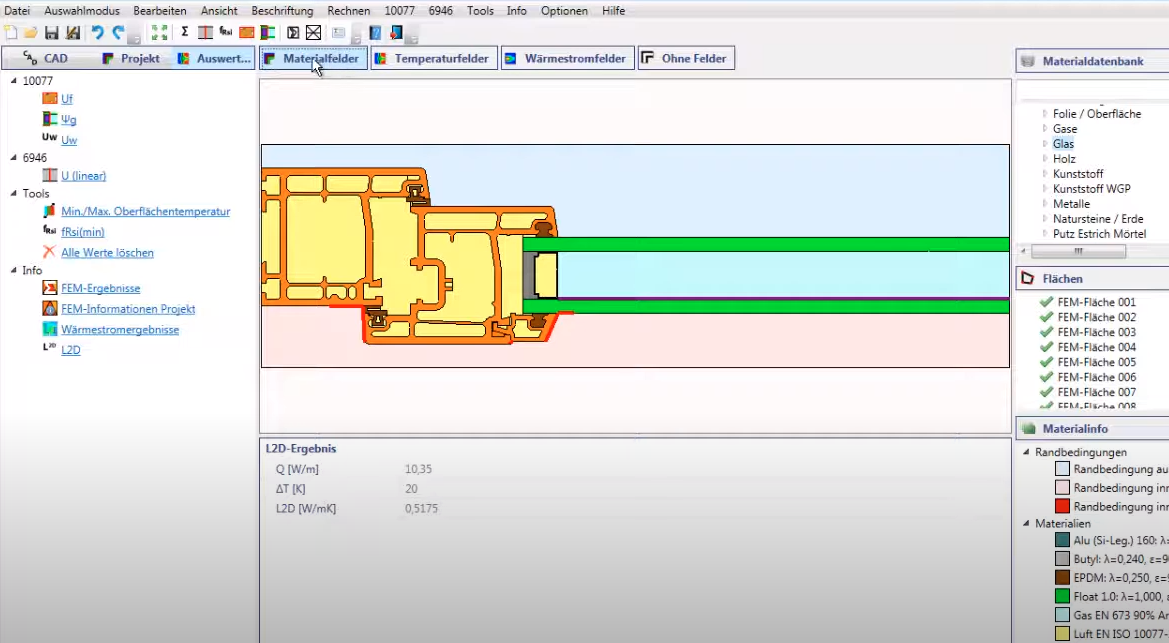

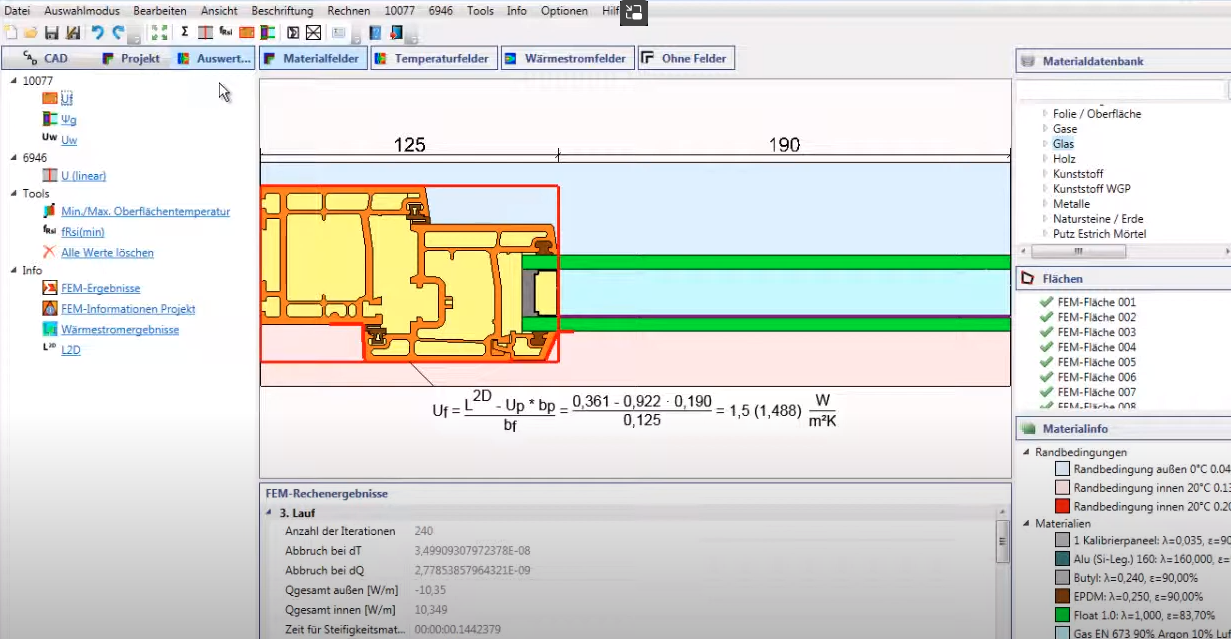

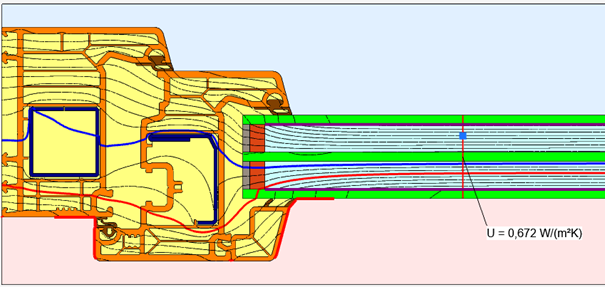

PVC-window: Uf and ψg according EN ISO 10077-2

Calculation of frame U value Uf and edge bond ψ value ψg according to EN ISO 10077-2 for a PVC window

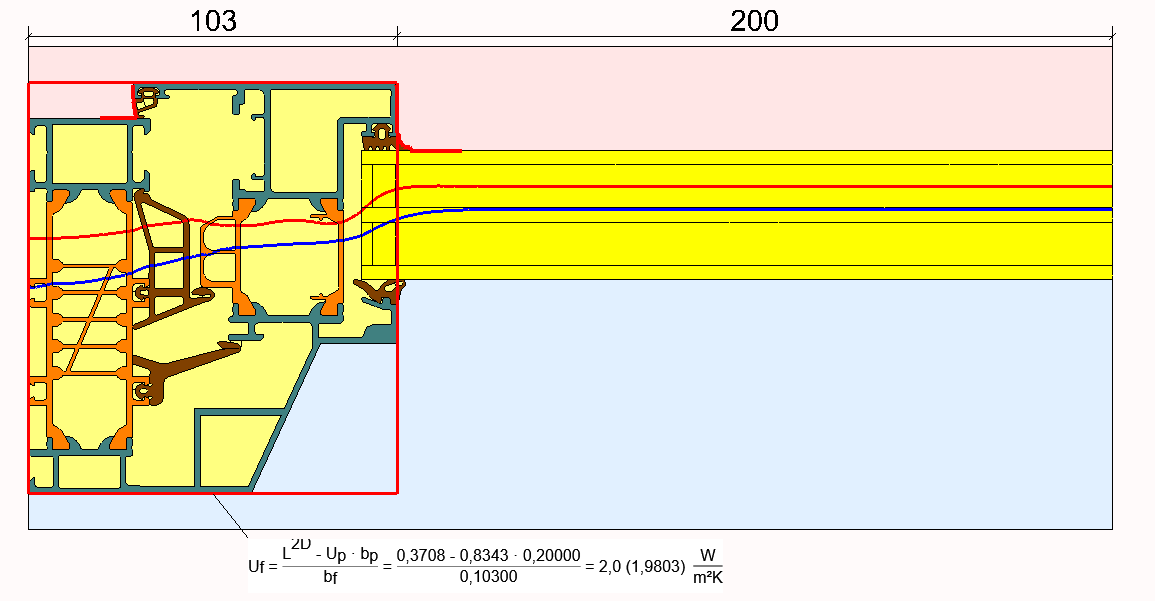

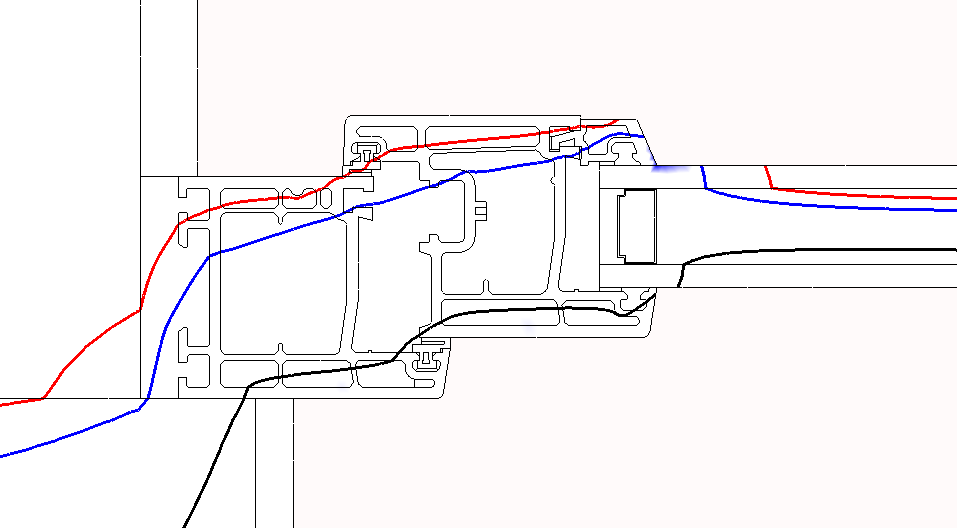

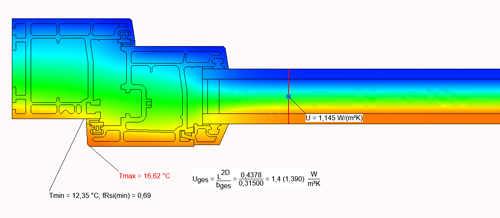

Alu-window:

Uf according EN ISO 10077-2

Calculation of frame U value Uf according to EN ISO 10077-2 for an aluminium window

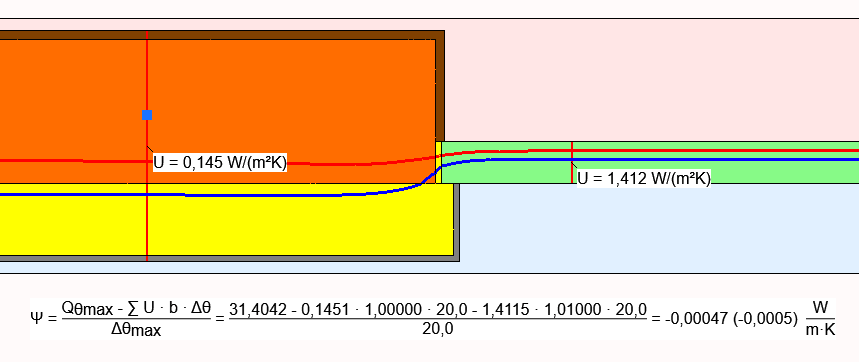

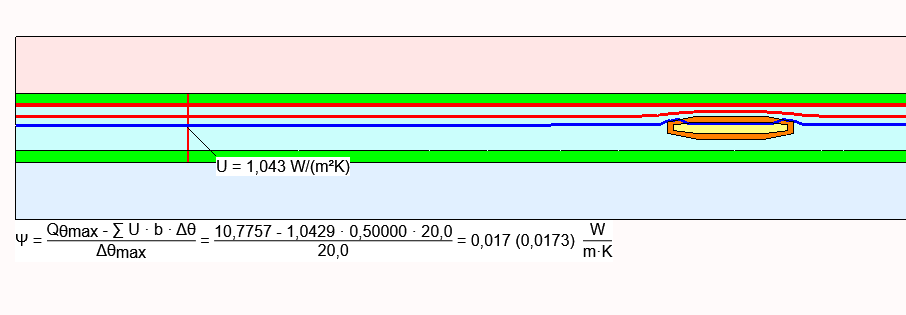

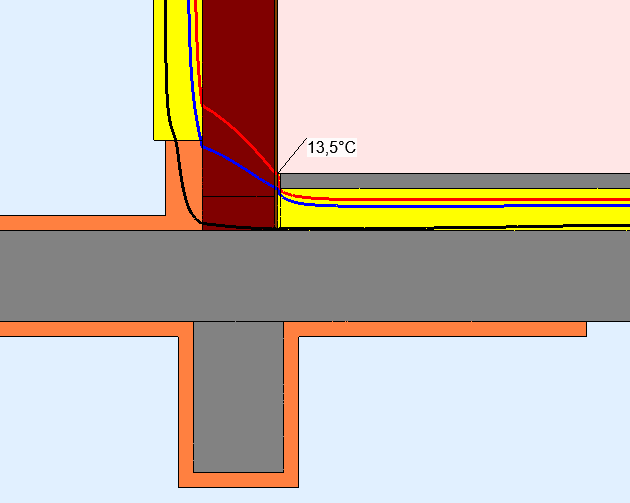

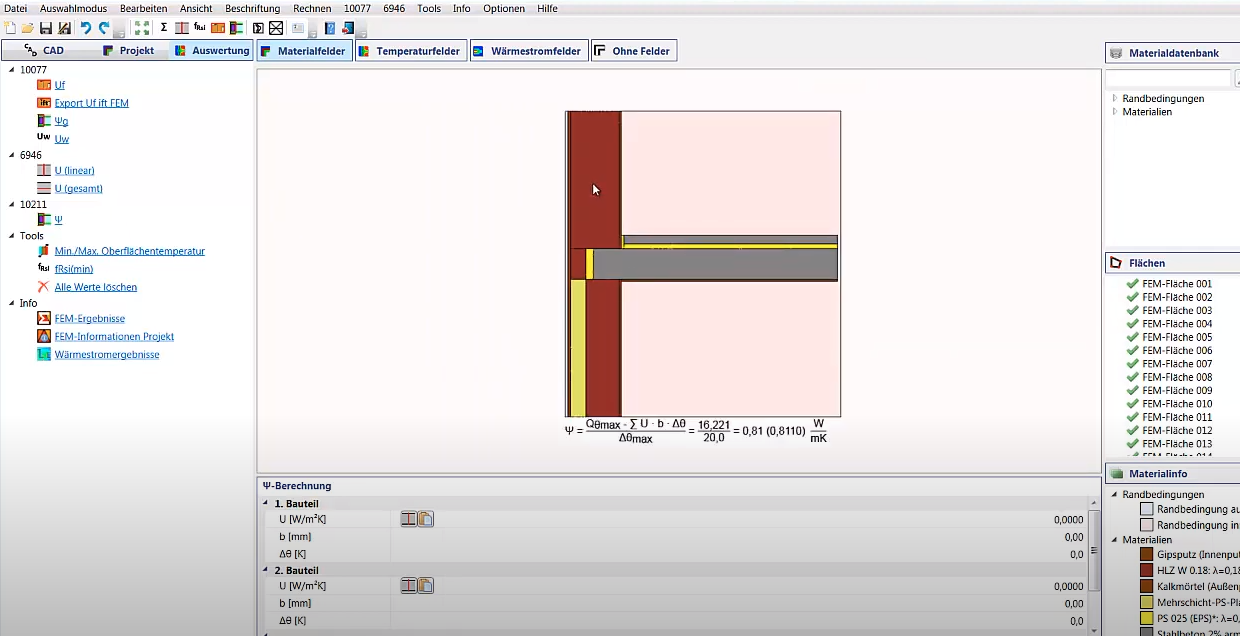

Window-installation:

ψ- and fRsi-value

Installation ψ value and temperature factor fRsi according to DIN 4108 supplement 2

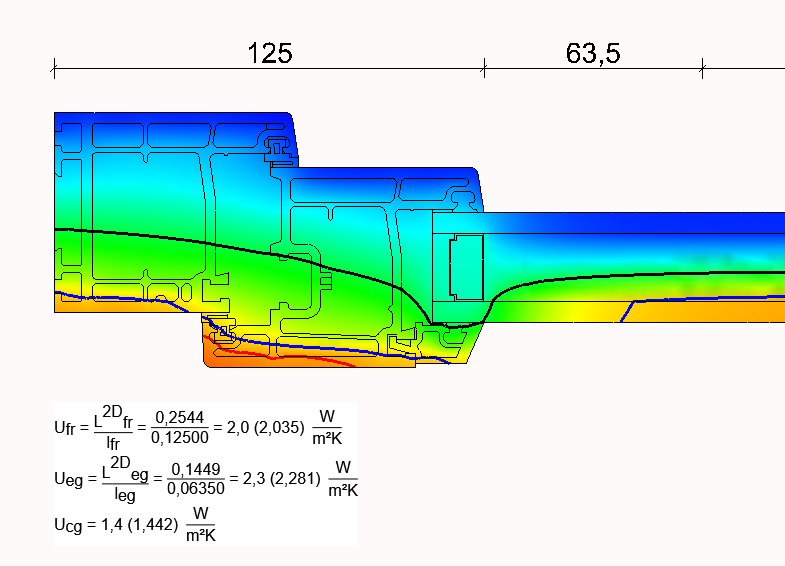

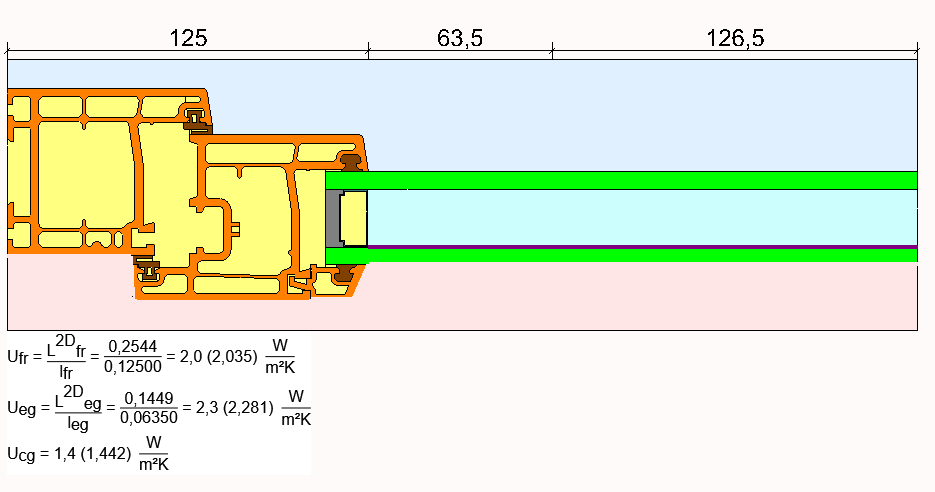

Window: Uw zone model according to ISO 15099

Calculation of the U values Ufr, Ueg, Ucg for the Uw zone model according to ISO 15099. Boundary conditions according to NFRC.

Window: Sash bar in glazing cavity

Thermal bridge at a sash bar integrated into the glazing air gap, accoding to ISO 10211.

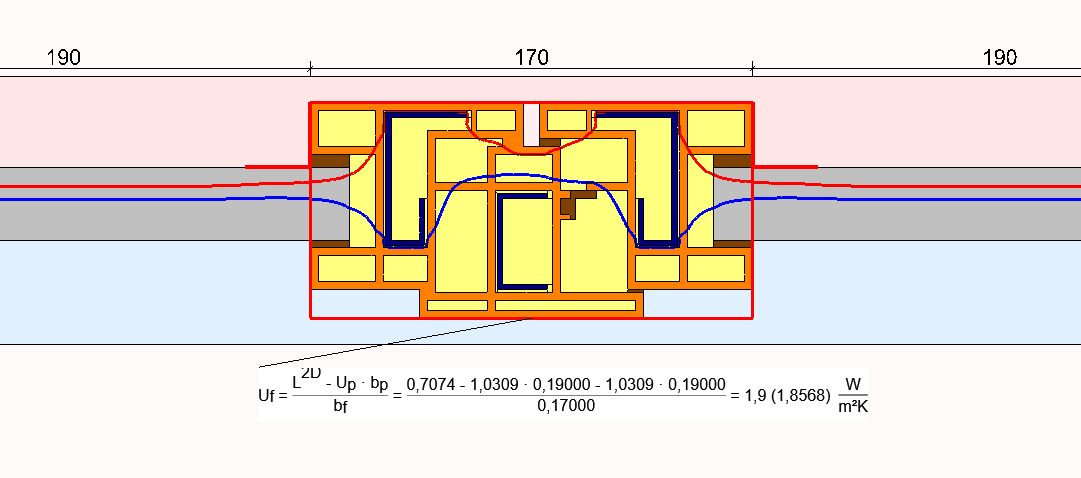

Window: Meeting rail with two glazing inserts

Automatic calculation of the Uf value of a meeting rail profile with two glazing inserts according to EN ISO 10077-2

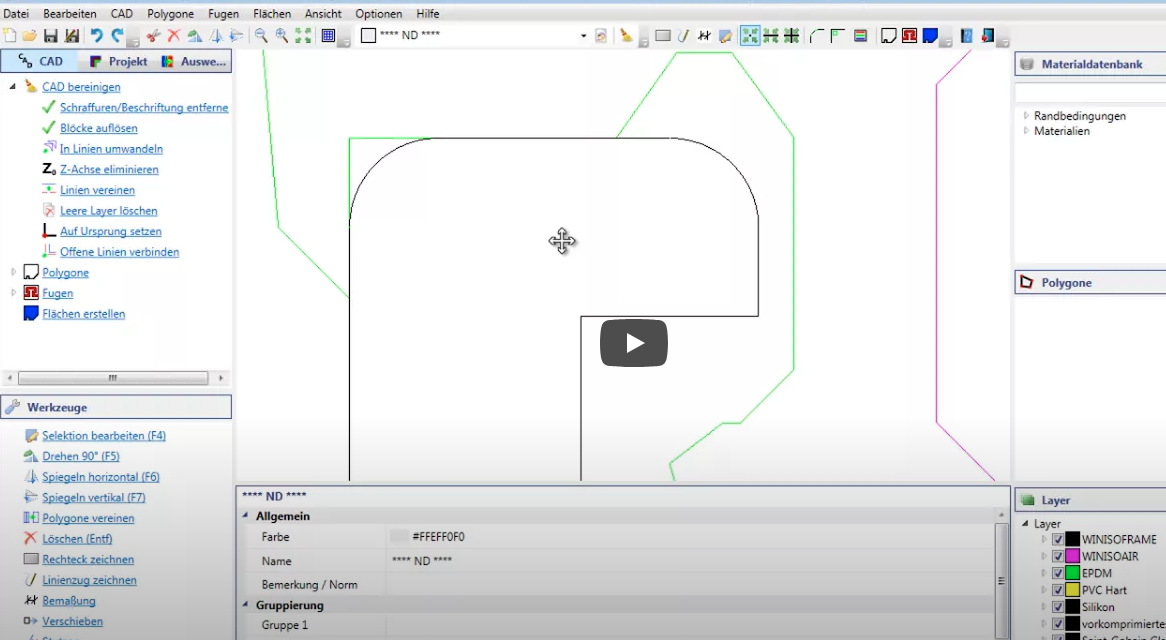

CAD import

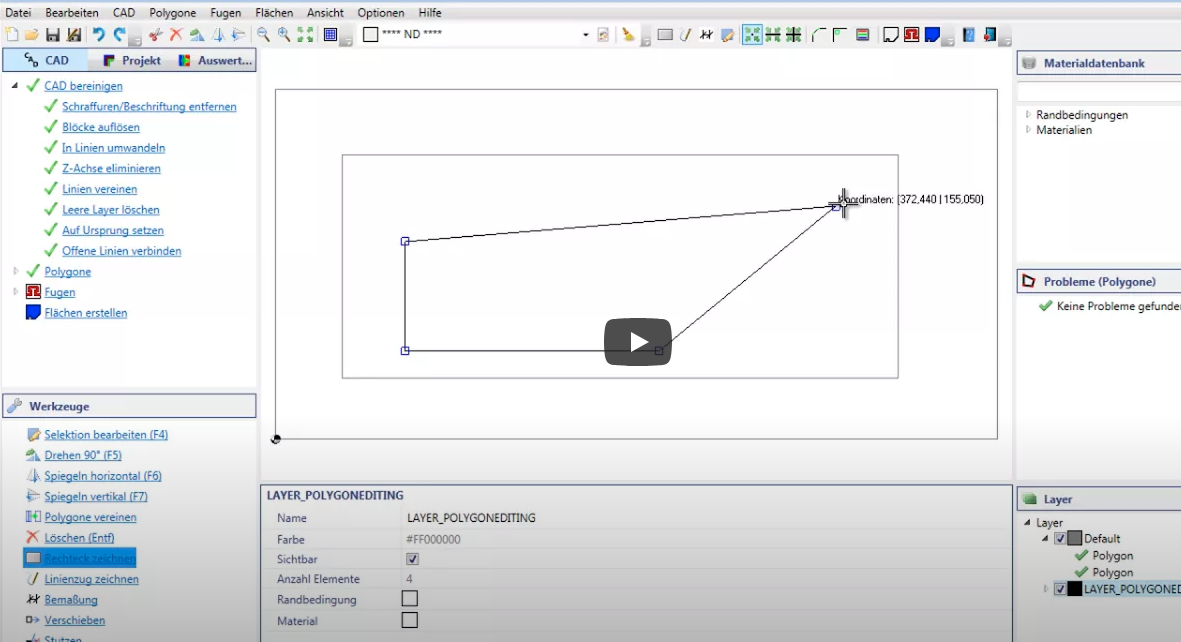

CAD import and clean up

WINISO® imports CAD data as DWG, DXF and STEP. Efficient tools for CAD preparation create a seamless transition from CAD to FEM during data transfer.

Polygons

During the generation and processing of the polygons, the essential features and contours of the design are obtained and the foundation is laid for efficient and fast FEM calculation.

Polygon Search Flood Fill

The Flood Fill polygon recognition gives the user an intuitive, powerful and robust tool for preparing even problematic CAD data.

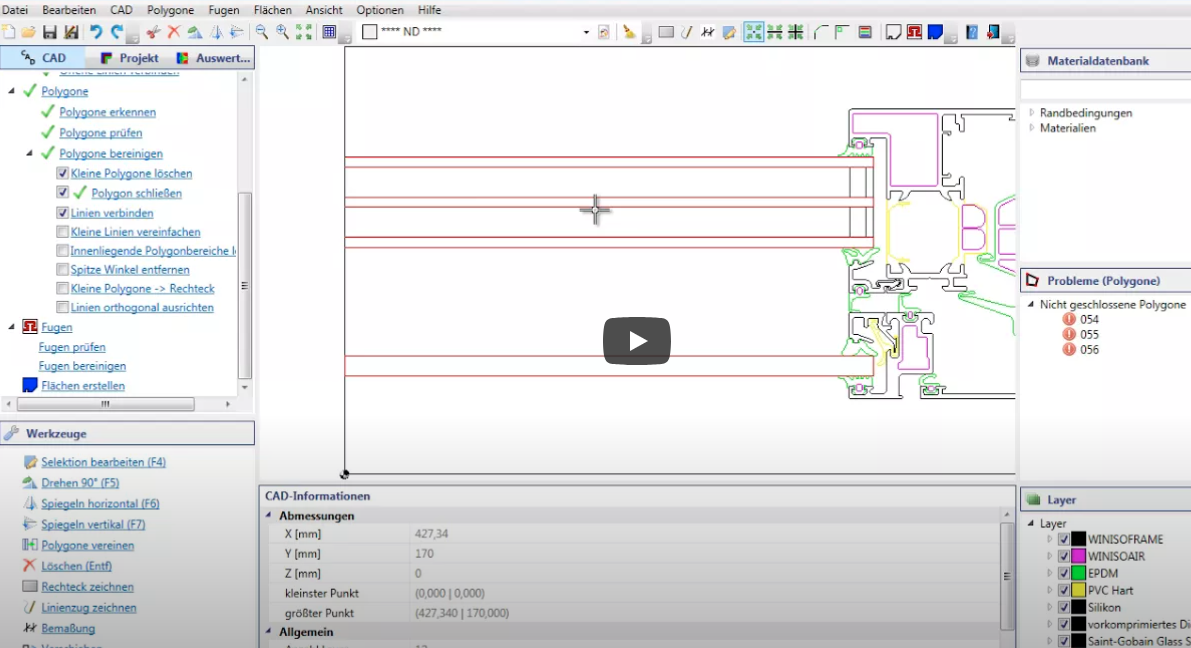

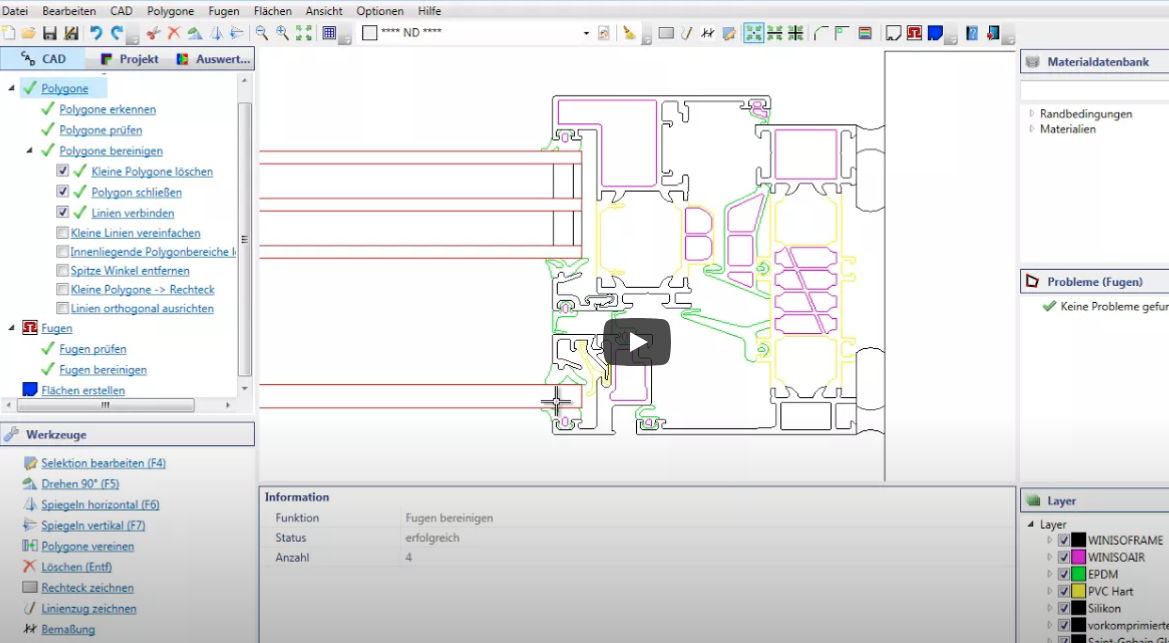

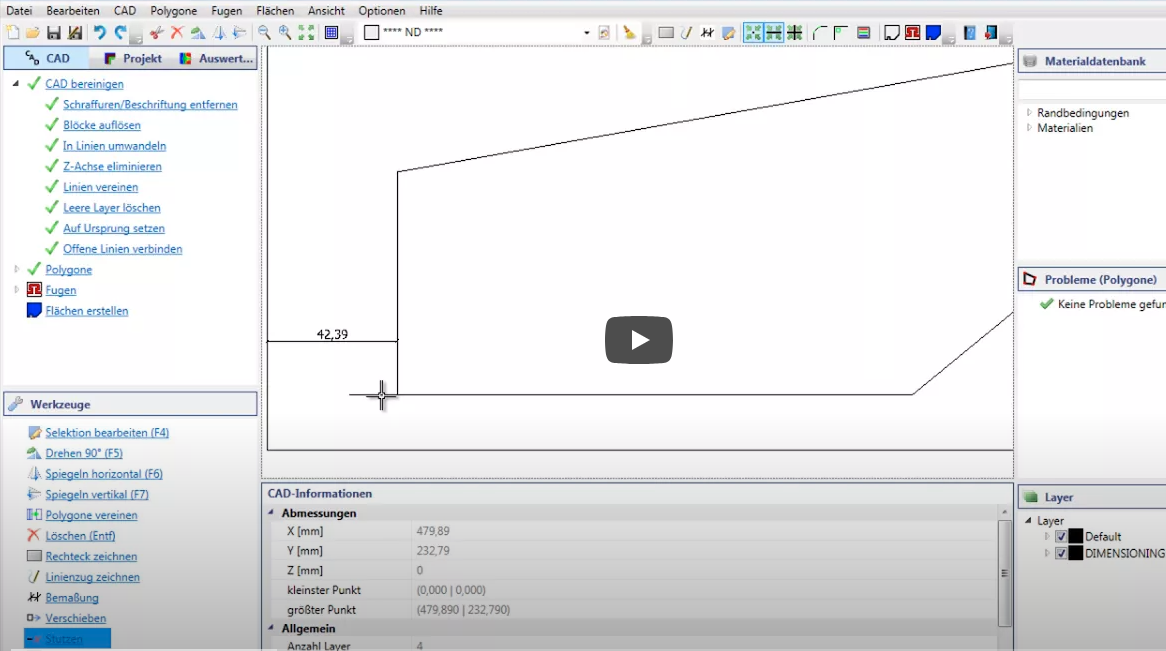

Clean joints

The joint clean-up automatically corrects offset errors from the CAD data and removes incidental details. The result is a coherent design that focuses on the essentials for the FEM calculation.

Tools – Part 1

With an extensive CAD tool set, the imported CAD data can be easily and flexibly reworked and supplemented

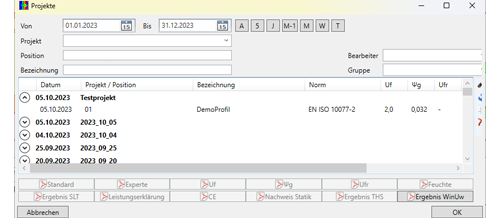

Project processing

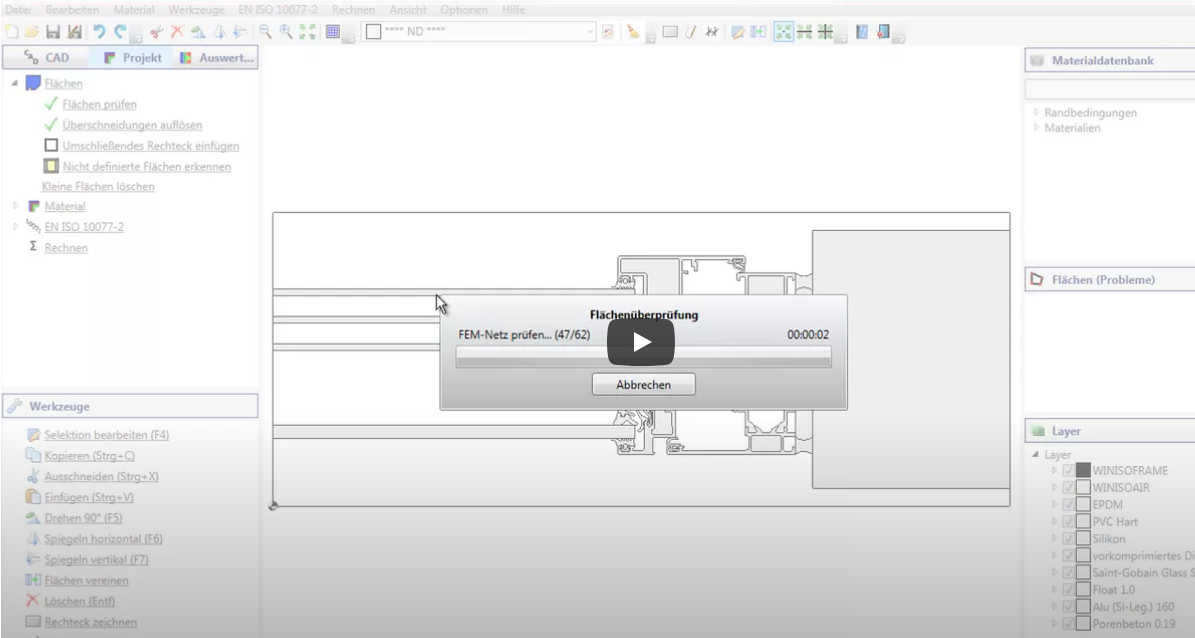

Surface machining

Surfaces reflect the geometry in the WINISO® FEM model. The structure of the simulation project is completely defined in just a few steps.

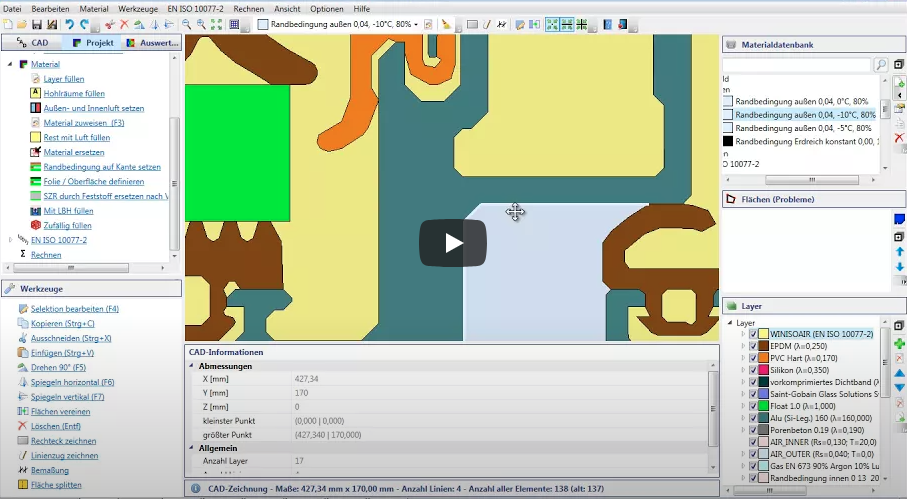

Material assignment

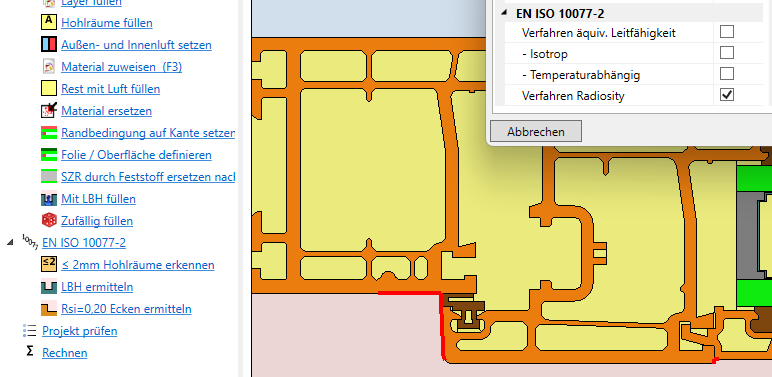

Automatic assignment of materials to layers and automatic detection of profile cavities and boundary condition surfaces for a speedy and error-resistant model definition

Boundary condition

With the automatic detection of cavities and the flexible definition of boundary conditions and surface properties, almost any problem can be modelled quickly and precisely.

Cavities

The definitions of frame cavities and spaces between panes from a wide range of standardisation are implemented in WINISO®: DIN EN ISO 10077-2, EN 673, DIN EN ISO 6946, ISO 15099.

Frame according to EN ISO 10077-2

WINISO® implements both calculation methods for window profiles with cavities provided for in DIN EN ISO 10077-2 in accordance with the standard: the equivalent conductivity method and the radiosity method introduced in 2017. Automatic checks ensure a consistent and standard-compliant calculation approach in all details.

EN ISO 673

The Ug value in the middle of the glass is determined in accordance with EN 673. This amended version DIN EN 673:2025-01 was published in January 2025. Until the revised version of EN 410 is published, Glass for Europe recommends continuing to use the version DIN EN 673:2011-04. The standard version is selected in the settings in WINISO®.

The corrected emissivity is now calculated consistently from the normal emissivity according to EN 12898, the physical properties of the filling gas according to ISO 52022-3. The reference value for the internal thermal resistance Rsi increases from 0.13 m²K/W to 0.14 m²K/W.

The determination of thermal transmittance through the frame and edge seal (Uf and ψg), isotherms, condensation and mold risk with WINISO® is possible with the current version of the SommerGlobal® building physics suite in accordance with the existing (2011) and new (2025) version of EN 673.

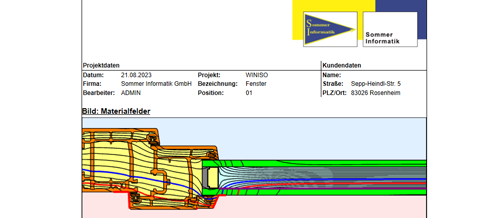

Reports

Presentation of results

Construction, temperatures, heat flows and humidity profiles can be represented flexibly and meaningfully by isothermal lines, false colours and isobars

Evaluation according to EN ISO 10077

The mathematical verification for windows according to DIN EN ISO 10077 can be carried out efficiently and in compliance with standards with the automated determination of Uf, Psig and Uw.

Certification ift Rosenheim

Evaluation according to DIN 4108 and EN ISO 6946

WINISO® provides elementary results such as the U-value according to EN ISO 6946 and the temperature factor fRsi according to DIN 4108:2 with one click

Present results

Present your results clearly and comprehensibly as a printout, PDF or in Word – with a set of predefined templates or customised with the template designer