WINISO®

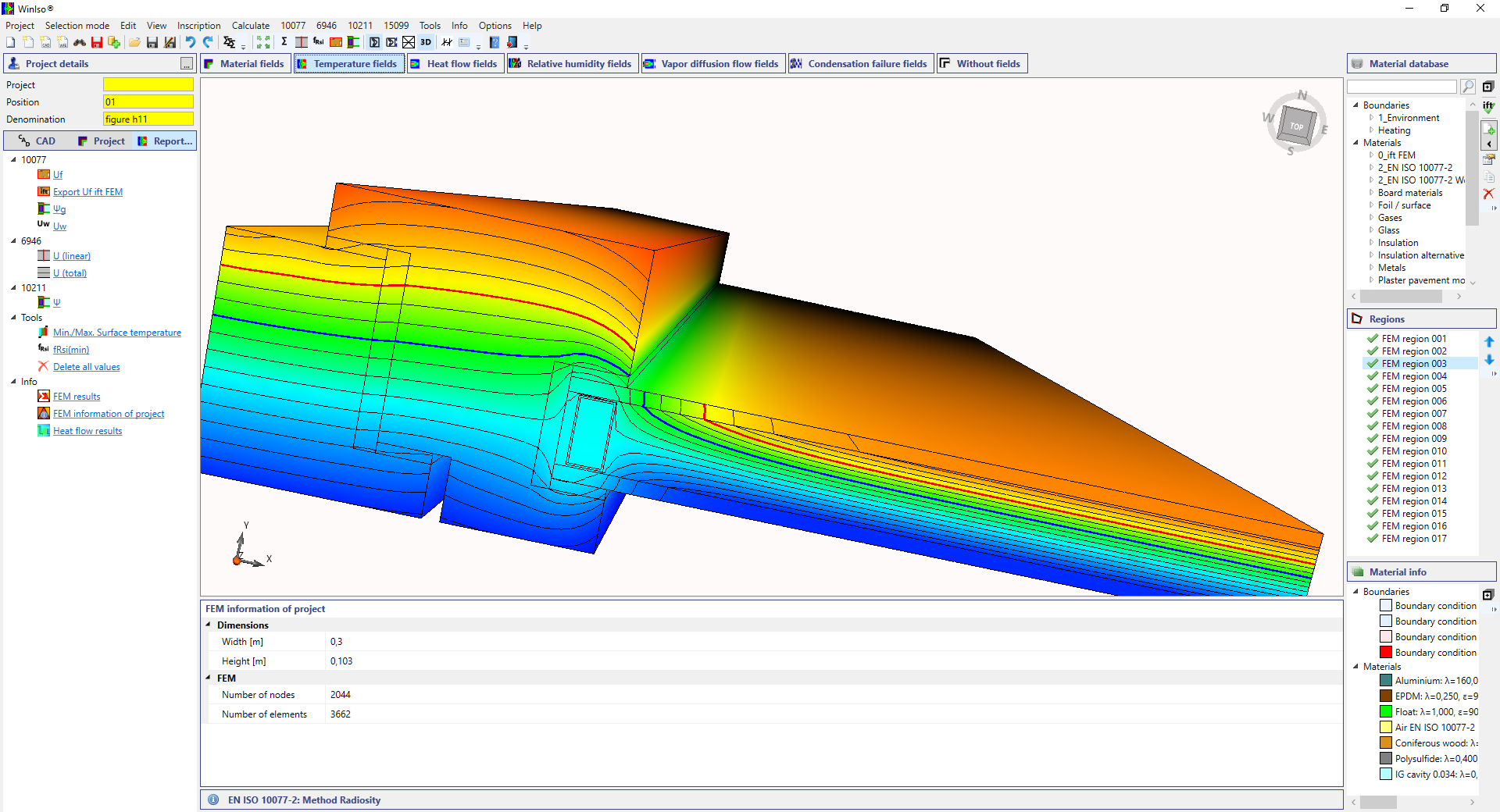

Proračun toplinskih tokova, toplinskih mostova, izotermi i Uf vrijednosti prema EN ISO 10077-2:2018 kao i Ufr, Ueg i Ucg vrijednosti prema ISO 15099 i NFRC.

Profesionalni izračun

Uf, Ψ, toplinski mostovi, izoterme, fRsi kao i vrijednosti Ufr, Ueg i Ucg

Potvrđeno

prema EN ISO 10077-2:2017-07 i EN ISO 10211-2:2017-07

Snažna funkcionalnost

za toplinski proračun prozora i fasada

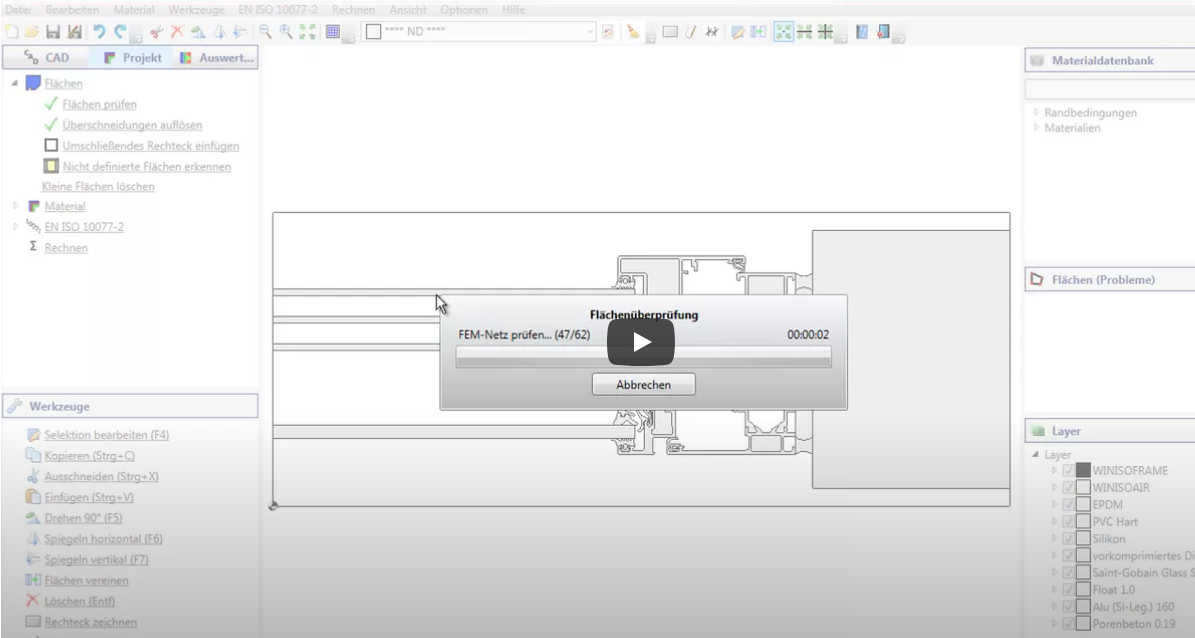

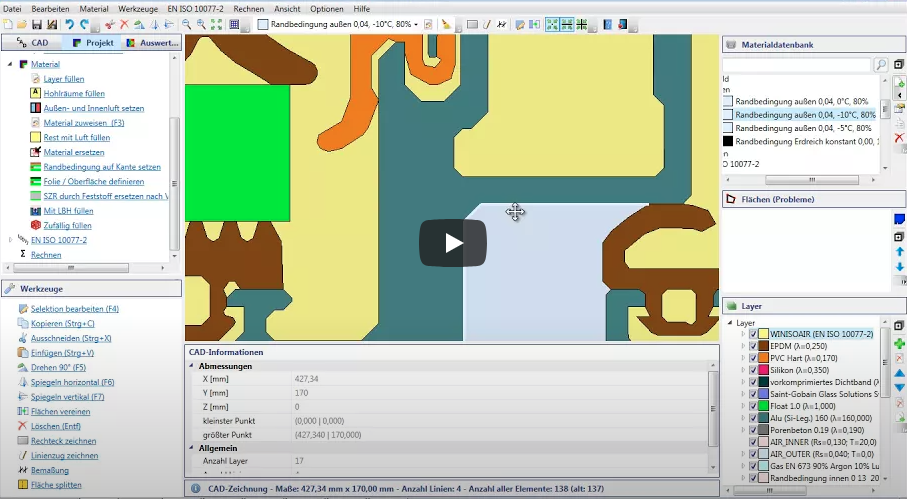

Uvezene CAD datoteke mogu se pripremiti automatskim otkrivanjem i ispravljanjem CAD pogrešaka. Stoga se komplicirane komponente i sustavi mogu analizirati i izračunati uz kratko vrijeme računanja i male veličine podataka. Integrirana jezgra FEM izračuna omogućuje najtočnije rezultate.

Značajke

- Visoko automatizirana priprema geometrije CAD podataka (.dxf & .dwg)

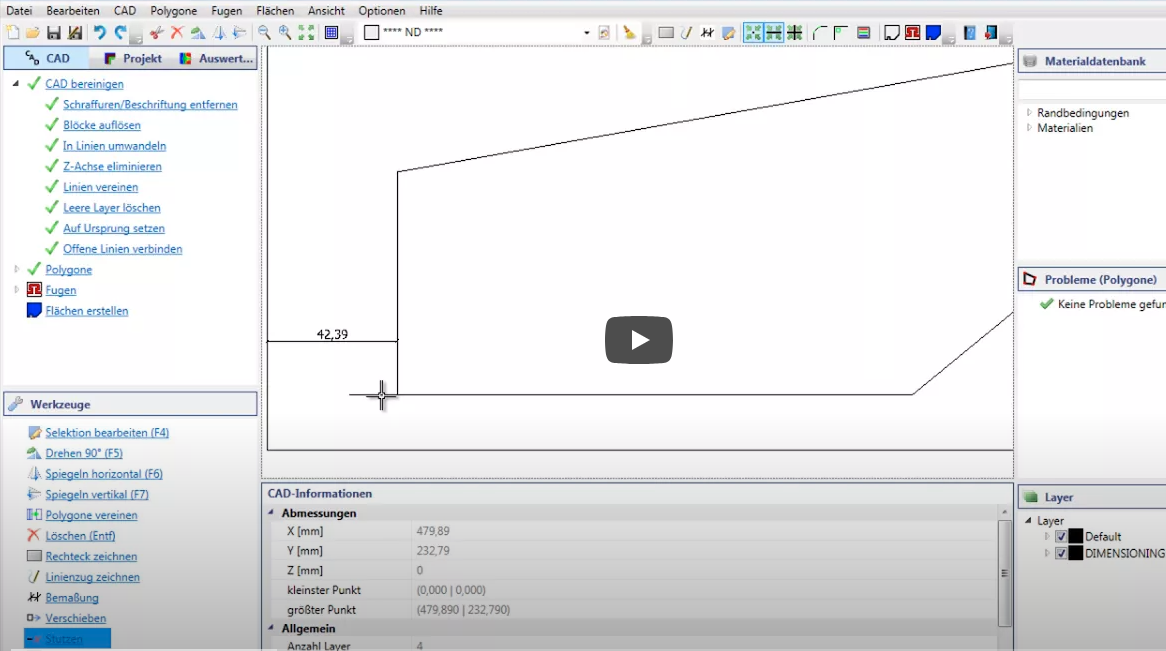

- Detaljan prijenos CAD podataka uklj. radijusi i kosine

- Novi alat za rješavanje i nova računska jezgra s automatskim MKE mrežama

- Automatskim FEM mrežama može se upravljati fleksibilno i specifično, što rezultira velikim brzinama izračuna

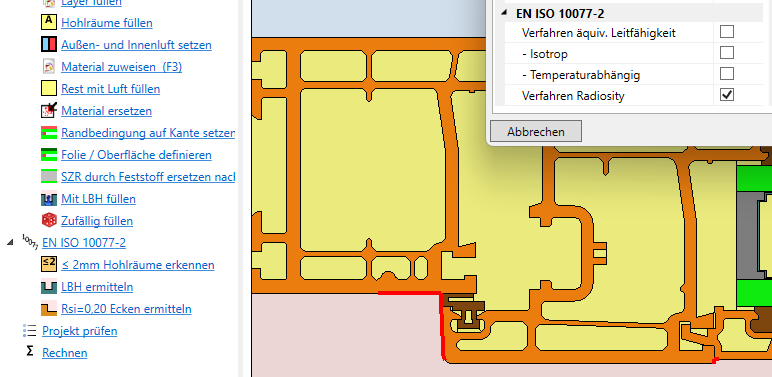

- Izračun prema "modelu radioziteta" (novi model šupljine prema EN ISO 10077-2:2018) i s ekvivalentnom vodljivošću (EN ISO 10077-2:2012/2018)

- Jednostavna definicija folija, premaza i površinskih svojstava pomoću crteža

- Automatska dodjela materijala na temelju CAD slojeva

- Plinsko punjenje za međustaklene prostore prema DIN EN 673 slobodno miješanje

- Automatski proračun Uf prozorskih i fasadnih profila

- Psi-vrijednosti toplinskih mostova i odstojnika izolacijskog stakla prema EN ISO 10211 i EN ISO 10077-2

- Ug-vrijednosti višeslojnog izolacijskog stakla prema EN 673

- U-vrijednosti bilo koje konstrukcije prema EN ISO 6946

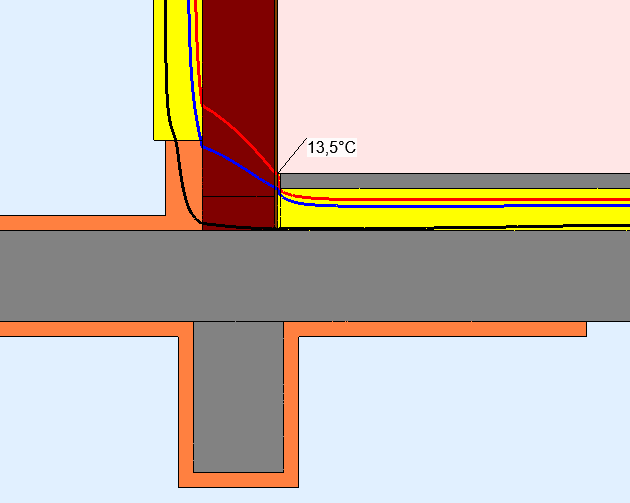

- Izračun izotermi, površinskih temperatura i temperaturnog faktora prema DIN 4108-2/-3

Testirajte našu demo verziju!

Zašto WINISO®?

- Certificirano od strane neovisnih instituta za testiranje

- Rezultati su međunarodno priznati

- Izuzetno jednostavan rad

- Pouzdan partner za dugoročno zadovoljstvo kupaca

- Rješenja spremna za tržište čak i prije donošenja relevantnih zakona i standarda, zajedno s stalnim ažuriranjem – naša su rješenja uvijek ažurna

Primjeri

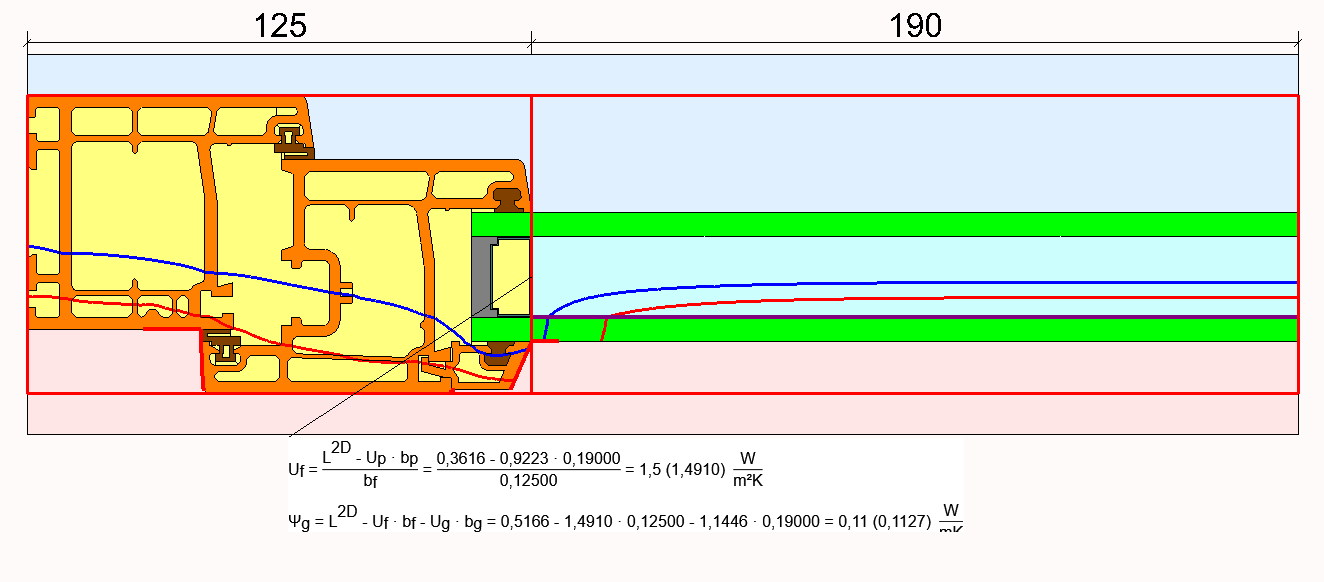

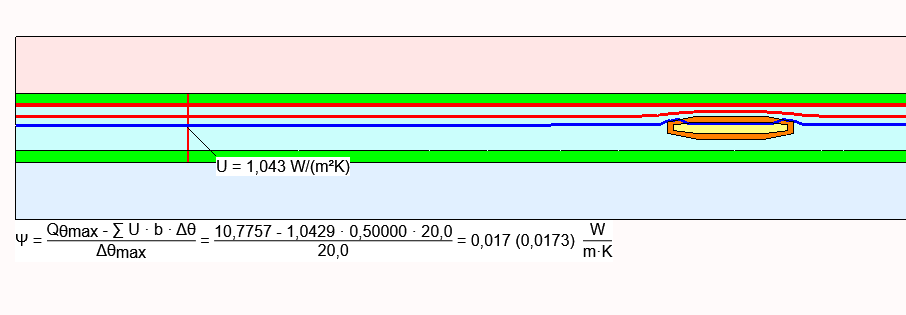

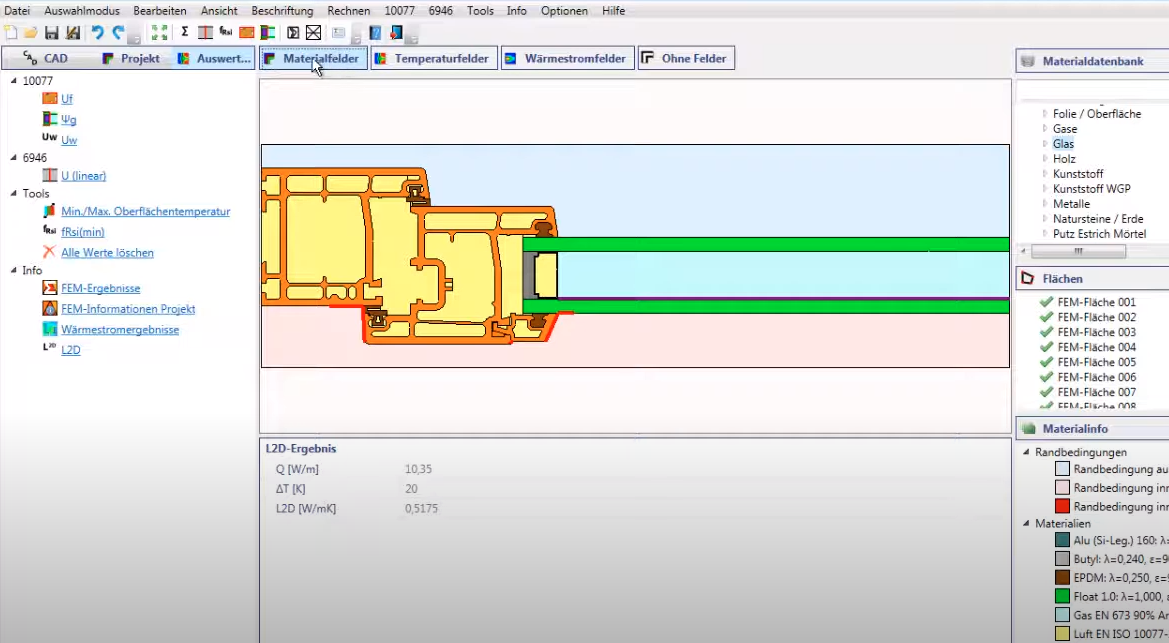

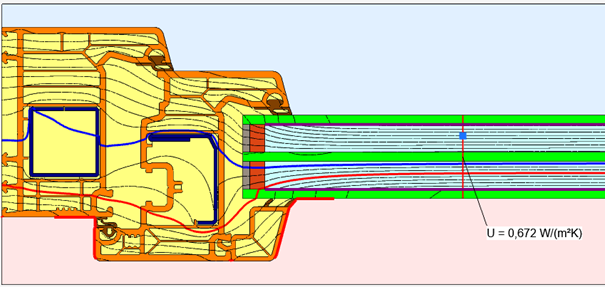

PVC-prozor: Uf i ψg prema EN ISO 10077-2

Izračun U-vrijednosti okvira Uf i rubne veze ψ vrijednosti ψg prema EN ISO 10077-2 za PVC prozor

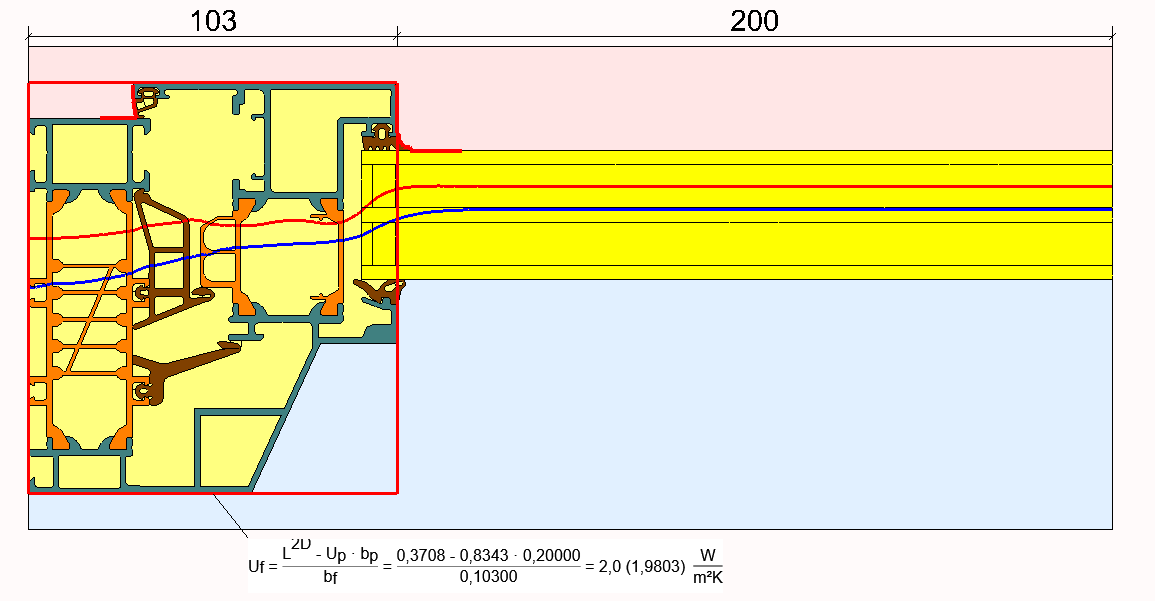

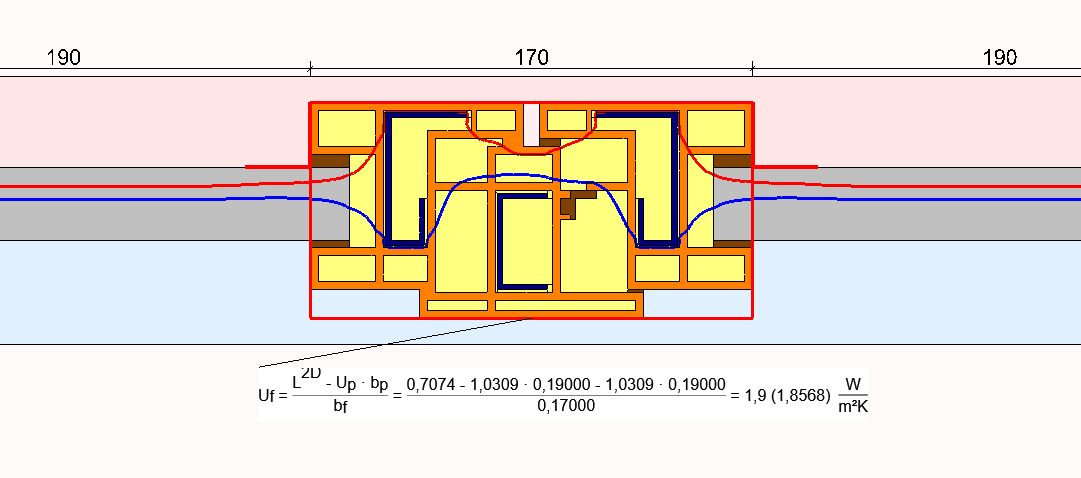

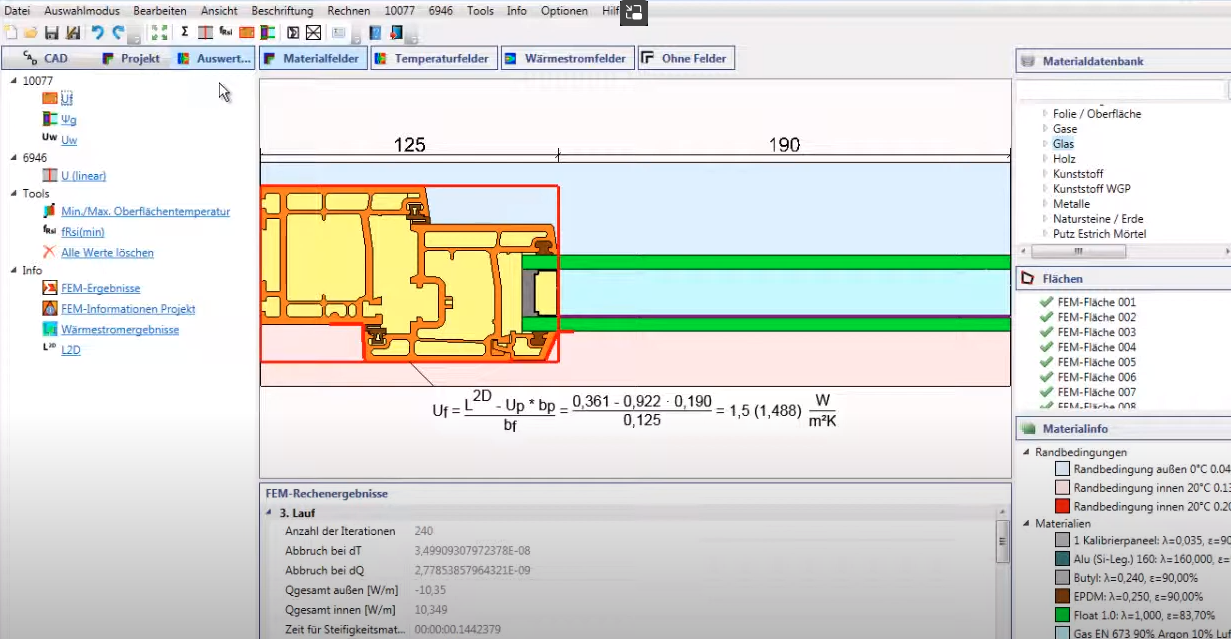

Alu-prozor:

Uf prema EN ISO 10077-2

Izračun U-vrijednosti okvira Uf prema EN ISO 10077-2 za aluminijski prozor

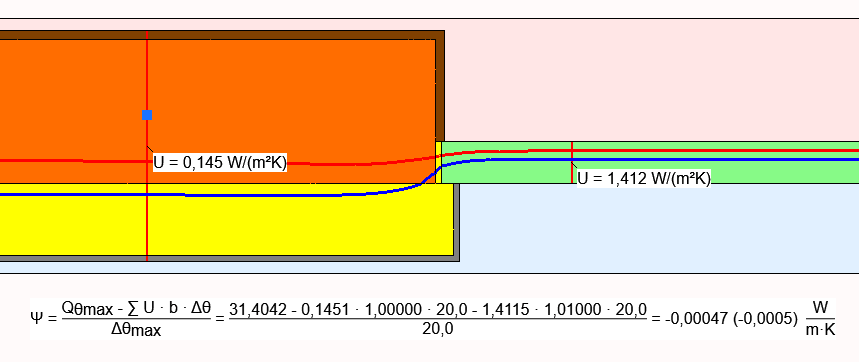

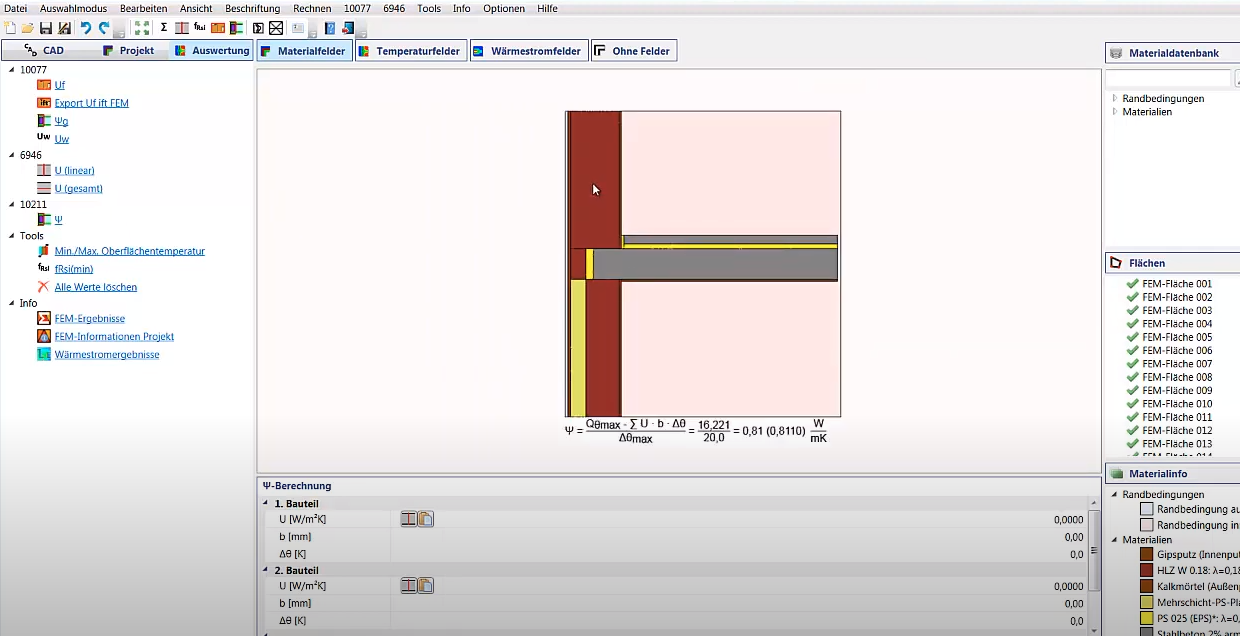

Instalacija prozora:

ψ- i fRsi-vrijednost

Instalacijska ψ vrijednost i temperaturni faktor fRsi prema DIN 4108 dodatak 2

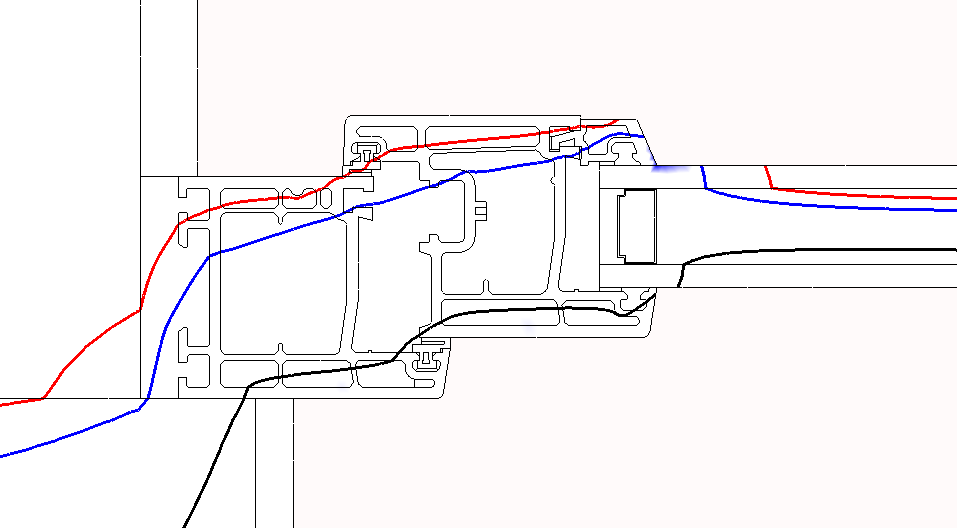

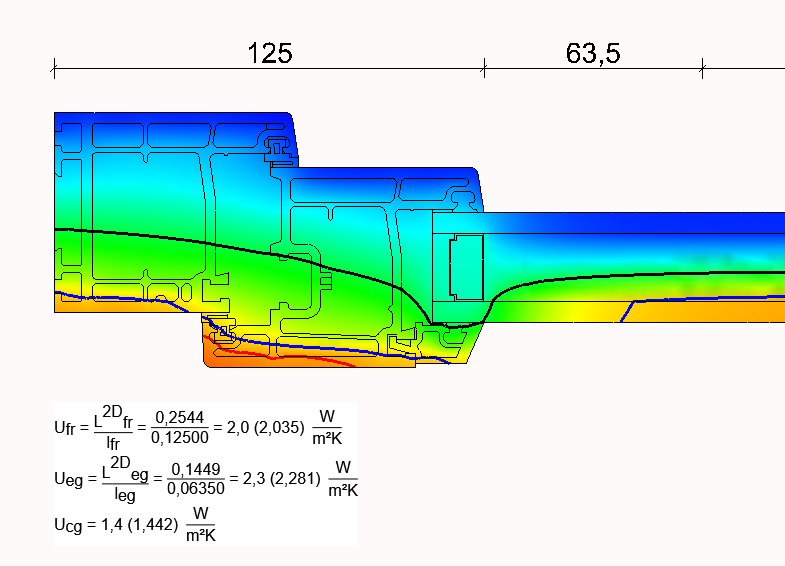

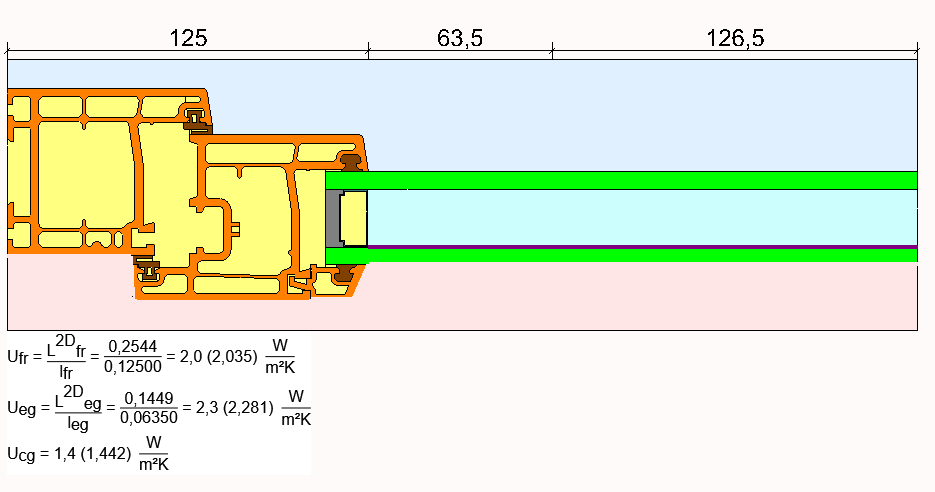

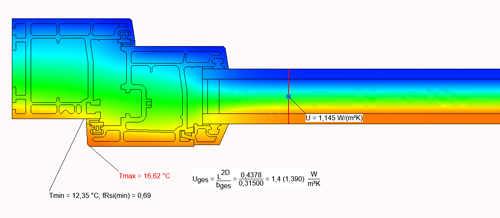

Prozor: Uw model zone prema ISO 15099

Izračun U vrijednosti Ufr, Ueg, Ucg za model Uw zone prema ISO 15099. Rubni uvjeti prema NFRC.

Prozor: krilo u staklenoj šupljini

Toplinski most na letvici krila integriranoj u zračni raspor ostakljenja, prema ISO 10211.

Prozor: tračnica za sastanke s dva staklena umetka

Automatski izračun Uf vrijednosti profila tračnica za susrete s dva umetka za ostakljenje prema EN ISO 10077-2

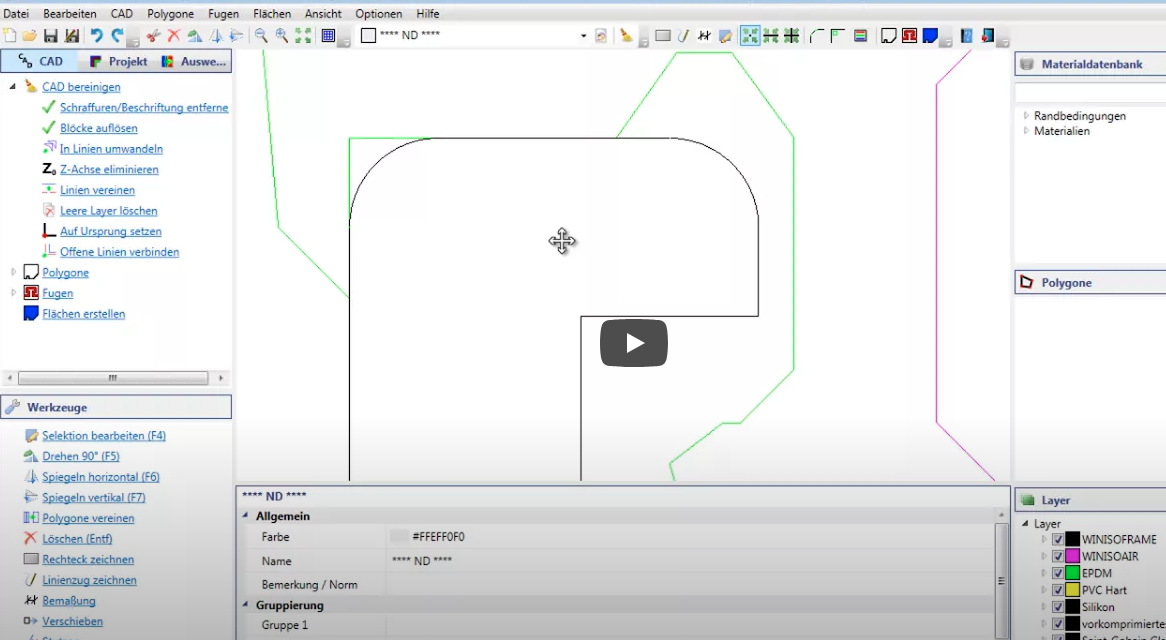

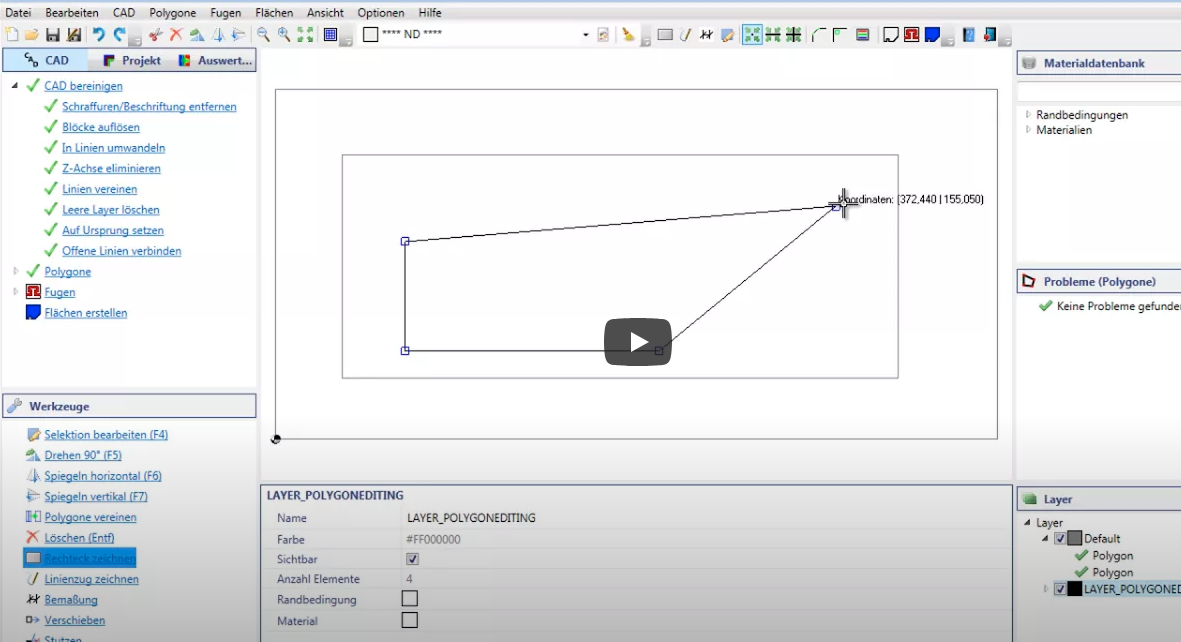

CAD uvoz

CAD uvoz i čišćenje

WINISO® uvozi CAD podatke kao DWG, DXF i STEP. Učinkoviti alati za CAD pripremu stvaraju besprijekoran prijelaz s CAD na FEM tijekom prijenosa podataka.

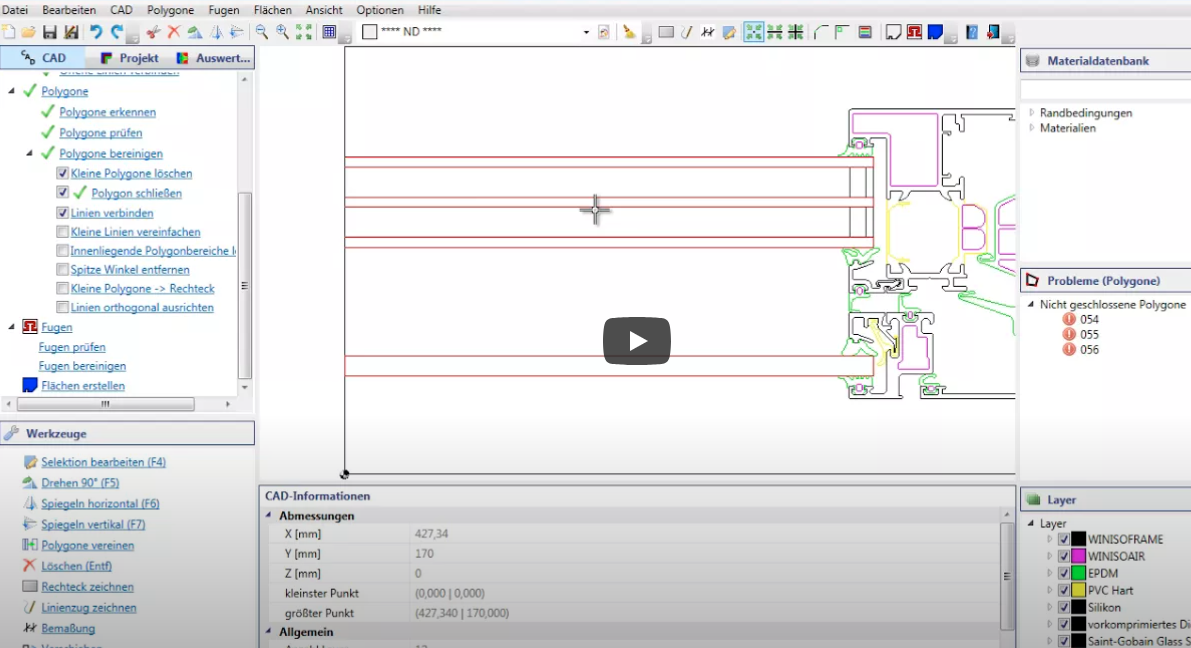

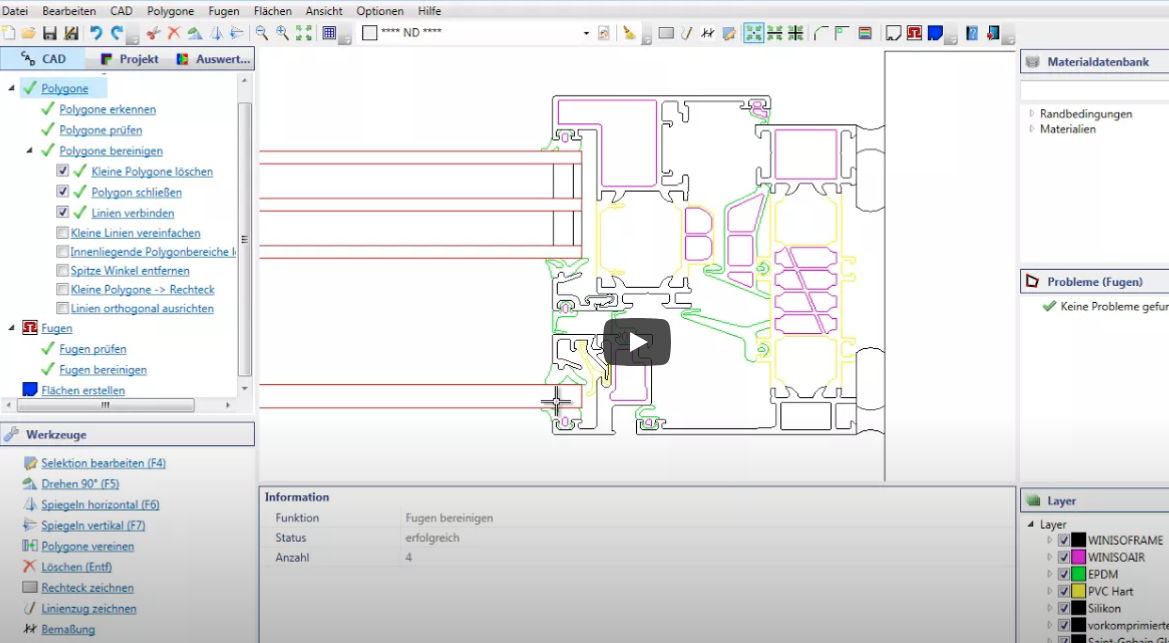

Poligoni

Tijekom generiranja i obrade poligona dobivaju se bitne značajke i konture dizajna te se postavljaju temelji za učinkovit i brz FEM proračun.

Očistite spojeve

Čišćenje spojeva automatski ispravlja pogreške pomaka iz CAD podataka i uklanja slučajne detalje. Rezultat je koherentan dizajn koji se usredotočuje na osnove za FEM izračun.

Alati – 1. dio

S opsežnim CAD skupom alata, uvezeni CAD podaci mogu se jednostavno i fleksibilno preraditi i nadopuniti

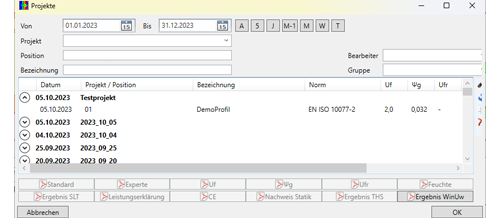

Obrada projekta

Površinska obrada

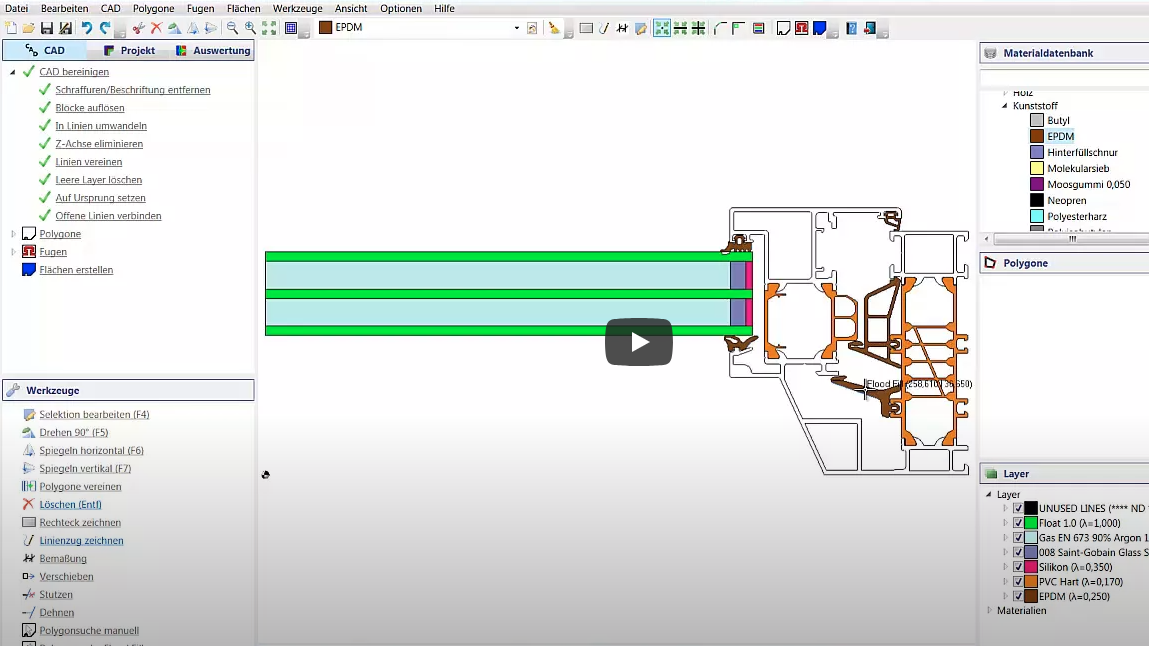

Površine odražavaju geometriju WINISO® FEM modela. Struktura simulacijskog projekta u potpunosti je definirana u samo nekoliko koraka.

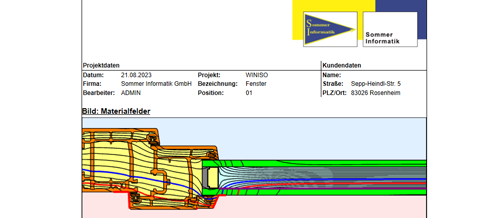

Materijalni zadatak

Automatsko dodjeljivanje materijala slojevima i automatsko otkrivanje šupljina profila i površina rubnih uvjeta za brzu definiciju modela otpornu na pogreške

Šupljine

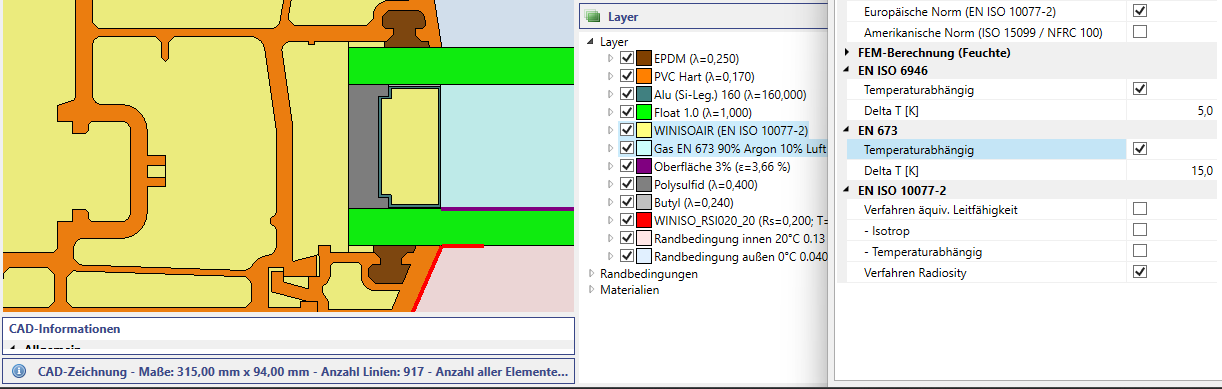

Definicije šupljina okvira i razmaka između stakala iz širokog raspona standardizacije implementirane su u WINISO®: DIN EN ISO 10077-2, EN 673, DIN EN ISO 6946, ISO 15099.

Okvir prema EN ISO 10077-2

WINISO® provodi obje metode proračuna za prozorske profile sa šupljinama predviđene u DIN EN ISO 10077-2 u skladu sa standardom: metodu ekvivalentne vodljivosti i metodu radijacije uvedenu 2017. Automatske provjere osiguravaju dosljedan i standardno usklađen pristup proračunu u sve detalje.

EN ISO 673

izvješća

Prezentacija rezultata

Konstrukcija, temperature, tokovi topline i profili vlažnosti mogu se prikazati fleksibilno i smisleno izotermalnim linijama, lažnim bojama i izobarama

Ocjenjivanje prema EN ISO 10077

Matematička provjera za prozore prema DIN EN ISO 10077 može se provesti učinkovito iu skladu sa standardima s automatskim određivanjem Uf, Psig i Uw.

Certifikacija ift Rosenheim

Ocjenjivanje prema DIN 4108 i EN ISO 6946

WINISO® jednim klikom daje elementarne rezultate kao što su U-vrijednost prema EN ISO 6946 i temperaturni faktor fRsi prema DIN 4108:2

Predstavite rezultate

Predstavite svoje rezultate jasno i razumljivo kao ispis, PDF ili u Wordu – sa skupom unaprijed definiranih predložaka ili prilagođenih pomoću dizajnera predložaka